Mold Manufacturing

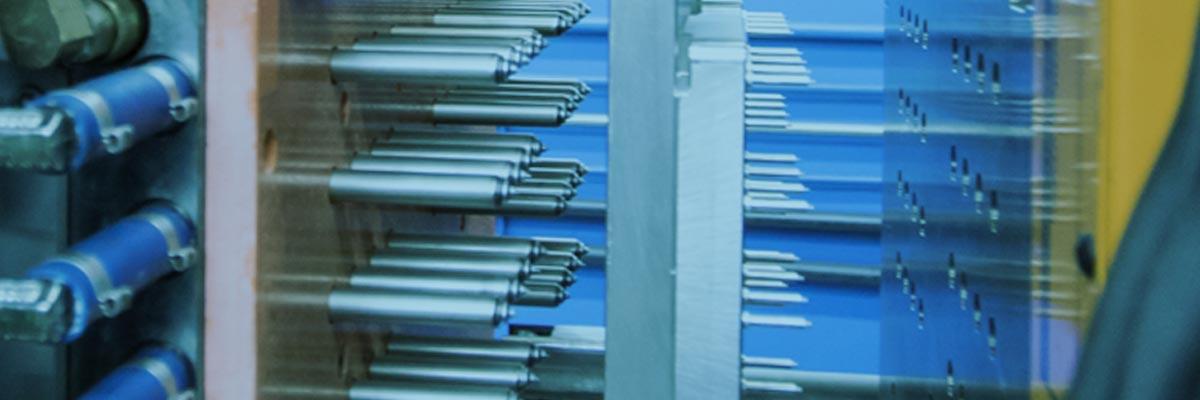

32-cavity valve gated cold runner mold with air blast part removalM.R. Mold is Southern California’s premier custom mold maker, specializing in the manufacture of tight-tolerance, high-quality Liquid Silicone Rubber (LSR) injection molds for the medical industry since 1985.

32-cavity valve gated cold runner mold with air blast part removalM.R. Mold is Southern California’s premier custom mold maker, specializing in the manufacture of tight-tolerance, high-quality Liquid Silicone Rubber (LSR) injection molds for the medical industry since 1985.

8-cavity valve gated cold runner mold with robotic EOAT part removal All molds manufactured at M.R. Mold are built using the Society of Plastic Industry (SPI) standards as a guideline. Each of our employees utilizes a unique skill set that contributes to the quality standard set forth by our management team. We specialize in the manufacture of LSR and plastic injection molds. We are committed to ensuring a successful project – something which our customers have come to expect from us as a world-class mold maker.

8-cavity valve gated cold runner mold with robotic EOAT part removal All molds manufactured at M.R. Mold are built using the Society of Plastic Industry (SPI) standards as a guideline. Each of our employees utilizes a unique skill set that contributes to the quality standard set forth by our management team. We specialize in the manufacture of LSR and plastic injection molds. We are committed to ensuring a successful project – something which our customers have come to expect from us as a world-class mold maker.

At M.R. Mold, we also believe in building prototype molds to prove out the production mold and automation. Our prototype molds are built with the same precision that your production mold will exhibit.